Getting fresh bread from frozen – tackling a challenge that’s never been solved

Saint-Germain

The Saint-Germain bakery opened its first store in 1970. The bakery uses carefully selected ingredients and works with them in a way that brings out their individual characteristics to the fullest. Loved by young and old alike, Saint-German now boasts several shops in the Tokyo metropolitan area. In July 2022, the bakery introduced Technican’s TOMIN to their business.

HIGHLIGHTS

-

Motive for introduction

Low revenue due to COVID-19

-

Usage

Limit food waste; market expansion

-

Products

12 types of baked goods, including Japanese rice buns with tamba bean, sausage rolls, bran donuts, walnut buns, and mayonnaise rolls.

-

Future Objectives

Development of online store for frozen bread

Contents

Fresh-baked bread is incredible, so why not find a way to freeze it?

“It wasn’t initially our intention to sell frozen bread. After all, we’ve always focused on providing the freshest bread possible,” explains Mr. Yasuda of Saint-Germain’s Store Operations Support Division. Bread generally has a short shelf life, and most bread that remains at the end of the day must be thrown away the following day. If you try to freeze it, at least with conventional air freezing, all the moisture is pulled out, leaving you with bread that is dry and lacking in both aroma and flavor.

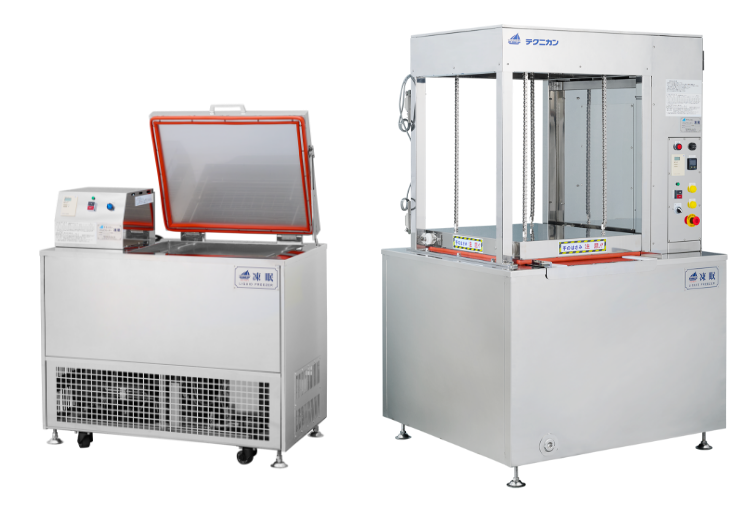

Foot traffic slowed due to the COVID-19 pandemic. During their search for ways to prop up revenue, Saint-Germain came across Technican’s TOMIN Liquid Cryo-Freezer. The TOMIN freezes substantially faster than conventional air freezing, limiting the expansion of water in food cells and preventing a decline in quality. The company decided to take the plunge with TOMIN, anticipating that it might be a viable solution to the problem of a short shelf life by helping them provide great-tasting fresh bread at any time.

After trying TOMIN Liquid Cryo-Frozen bread, Mr. Yasuda said: “There’s almost no difference – every bit of the quality remains”.

Customers who live alone and who are fans of Saint-Germain usually stock up on bread at the bakery, but now they can buy frozen bread that tastes great even after being stored in the freezer.

Innovation that preserves flavor

Baked goods are bagged one by one and then vacuum-packed to remove as much air as possible. This helps prevent spoilage and to preserve quality during storage. Throughout this process, it is important to maintain a balance between removing enough air and yet not allowing the pressure exerted by the packaging to crush the product. After all, softness and texture are crucial to the quality of these baked goods. Mr. Yasuda added, “Right now, vacuum packing is a manual process. But in the future, I would like to make it more efficient with a machine that automatically adjusts the amount of air removed.”

Freeze in just 45 minutes!

Saint-Germain says that it takes 45 minutes to freeze their bread with TOMIN Liquid Cryo-Freezing. Bread contains air, so freezing takes a little longer than with other types of foods. However, it’s still faster than conventional air freezing. After TOMIN Liquid Cryo-Freezing, the liquid is simply wiped off the packaging before the products are stored in the freezer.

Expiration date issues

The baked goods industry is known for a high rate of food waste because the products have such short shelf lives. Saint-Germain has been working for some time to minimize food waste and has opened a factory outlet. Products that are not of sufficient quality to be sold in the main store are offered at reduced prices in the factory outlet.

The TOMIN enables frozen storage and extends expiration dates to reduce food waste further.

However, no matter how you slice it, determining how to set the expiration dates for frozen bread takes time.

“In order to set an expiration date, you need to track the day-by-day deterioration in quality following the date of manufacture. Until we determine what the expiration dates should be, we can’t plan and optimize production, meaning there are products that we can’t bring to market. We estimate that expiration dates should be set at around one year, but we are at a standstill until testing is complete,” Mr. Yasuda explains with frustration. His company purchased the TOMIN just recently, so there’s only a few months worth of data available. But once expiration dates have been set, the business will be in a position to manage stock systematically and to start streamlining.

Production line issues

Saint-Germain’s production site has two adjacent workshops: a small one primarily for undertaking manual tasks, and a larger one for mechanical operations. The TOMIN currently remains in the smaller workshop.

It’s not safe to transfer the bread once it’s frozen. Even though the larger workshop is just a stone throw’s away, every product in the small workshop must be frozen and stored.

Mr. Yasuda explains, “We’re really in a challenging position, as it is barely possible to work in such a small space. Once the expiration date is determined, we’ll install further TOMIN freezers into the larger workshop (the one with mostly mechanized processes). And then we will be in a great position to expand!”

Review the plan, review the workflow, and make progress little by little. The results will soon begin to manifest themselves. Taking time to confirm expiration dates is a necessary step toward more significant results.

You can’t win if you don’t try! Working toward market expansion.

A major benefit of introducing the TOMIN is market expansion. Saint-Germain is also making preparations to sell bread online. “Our first step will be selling right from the display case at the store. And if we get an online order, we’ll simply ship it from stock.”

The bakery has also been selling at Takashimaya Shinjuku since September 2022. They report that the owner was immediately excited about frozen bread because that would be an entirely new product line. What’s more, the bakery would like to set up a vending machine for frozen baked goods. These are just some of the steps Saint-Germain is taking toward market expansion.

There are very few frozen bread distributors in the market, and there are many issues left to resolve. When asked where he wishes to go from here, Mr. Yasuda laughs and says, “I guess we’re going global.” At Technican, we pledge to do more than just provide our machine to Saint-Germain; we also intend to continue supporting this bakery.