Freeze test of solid beef tongue and pork belly for in-house processing and distribution

The customer who ordered this freeze test was starting a new business. This featured an izakaya (Japanese-style pub) along with the sale and distribution of both meat and side dishes. The owner used to be a meat wholesaler and used a cold-air rapid freezer in this business, but the loss in quality was concerning. While searching for a freezer that would limit the loss in quality to support the new venture, the owner came across some information regarding the TOMIN liquid freeze test.

Freeze Test HIGHLIGHTS

-

Customer’s

businessIzakaya operation + meat and side dish retail

-

Products

tested• Solid imported US beef tongue

• Solid imported US pork belly -

Objective/

improvement task• Loss of meat quality due to air freezing

Contents

Freeze test objectives

The customer who ordered this freeze test was starting a new business. This featured an izakaya along with the sale and of meat and side dishes. The owner used to be a meat wholesaler and used a cold-air rapid freezer in this business, but the loss in quality was concerning. While searching for a freezer that would limit the loss in quality to support the new venture, the owner came across some information regarding the TOMIN liquid freeze test.

Checkpoints

The foods tested were imported US beef tongue and imported US pork belly for processing in-house. The meat was imported raw from the United States. We conducted a TOMIN freeze test when we froze it here in Japan.

Checkpoints

• Longevity of TOMIN Liquid Cryo-Frozen meat quality

(flavor, texture, color after thawing, etc.)

Test process

① Interview

You share with us what you would like to achieve with TOMIN Liquid Cryo-Freezing.

② Freeze test of products you have provided

A series of processes including packaging, vacuum sealing, and freezing is conducted, replicating the actual TOMIN Liquid Cryo-Freezing process.

③ Demonstration

Liquid freezing tests and tastings are conducted using products prepared by Technican (various meats, sashimi, fruits, milk, gelatin, etc.).

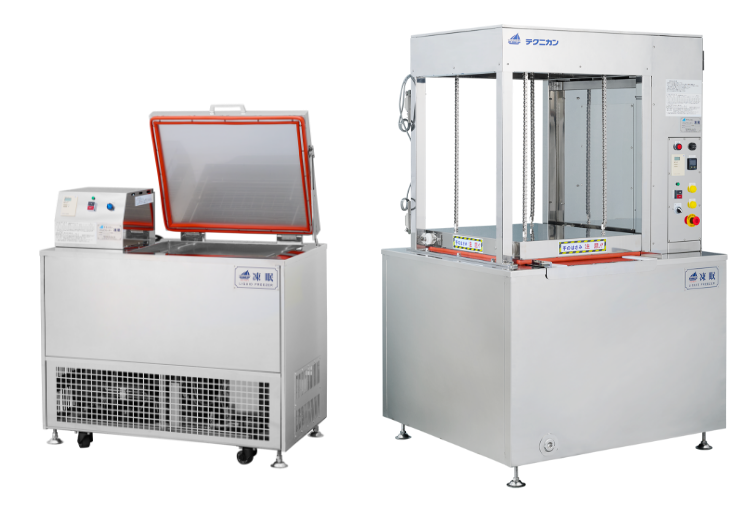

④ Freezer model explanation

There are several models of TOMIN freezers. They vary in the volume of product they can freeze per hour. We suggest a model based on the client’s needs.

⑤ Interview

We hold a Q&A session and provide our catalog.

⑥ Shipment of products you provided

Upon request, we can deliver the items you provided via TA-Q-BIN’s frozen shipping service.

Drip loss from meat

All food cells contain water. Conventional air freezing is a slow process, which gives the water time to expand and thus rupture the cells. When the food is then thawed, moisture flows out as drip loss, and this is how all the delicious flavor is lost.

TOMIN technology accomplishes the freezing process substantially faster than conventional air freezing methods. This minimizes the expansion of water in the food’s cells, resulting in a product that very faithfully reproduces the great flavor that the food possessed when fresh..

Frozen food can be thought of as sub-par, but liquid freezing with TOMIN has the power to change that notion.

Freeze test reactions

For the demonstration, we froze different types of meat in the TOMIN several months ago. We thawed them under running water, TOMIN liquid froze them again, and repeated the water-thawing process twice before the taste test.

The customer shared their impression that the meat definitely tasted different from meat frozen with the rapid air-freezing technology they’ve been using up until now. They also commented that there was no loss in freshness or flavor.

One of the issues with conventional freezing of meat is that it quickly loses its color and dries out after thawing. However, the fact that our clients already include several Japanese barbecue restaurants is proof that TOMIN technology is making a great contribution toward the distribution of perishable foods.

Freeze tests results often surprise our customers.

Please contact us for more information.