[ Hanasaki Crab x TOMIN ] Liquid Freezing in boiled state

We would introduce an example of implementation at Seibu corporation, a seafood processing company in Nemuro City, located at the eastern end of Hokkaido.

要約すると・・・

-

製造工程

トゲがあってもパックできる。だから凍眠凍結が可能!

-

導入のキッカケ

お取引先から「凍眠で冷凍して」と要望があったから

-

冷凍品質は?

取引先も大絶賛!スタッフも試食したが、冷凍品と非冷凍品との区別がつかないクオリティ!

Contents

Production processes

Pre-processing (Boiling)

Where crab leg meat is stuffed into the shell and frozen. The crab is pre-boiled so that it can be eaten immediately after thawing.

Can it be packaged despite the spines?

Yes, it can! When freezing spiny products like crabs, options include changing the thickness of the vacuum packaging material or choosing highly stretchable materials. At Seibu corporation, they leave some air in the packaging, place it in a plastic container, and top-seal it.

Stuffing the meat into the shell

Primary packaging

Secondary packaging

Sterilization with steam

Rapidly liquid freezing with TOMIN

The optimal condition for freezing with TOMIN is “vacuum packaging.” In other words, the best state is when there is no air in the package. There are two reasons for this. First, air has weak heat exchange power. In a sense, air can be said to have insulation properties. Therefore, if there is air left in the pack, it is difficult to utilize the heat exchange power of the liquid, which is the greatest advantage of liquid freezing. It is said that liquid cooling is faster than air cooling in terms of freezing speed, and this heat exchange is the key point. Second, the presence of air increases the risk of freezer burn.

So, does the air in this package mean it’s suboptimal? Not necessarily. Vacuum packaging is ideal, but if it is challenging in operations, it can be flexibly handled. In this product, although it contains air, the surface area in contact with the liquid (alcohol solution) through the packaging material is sufficiently secured, allowing rapid freezing. As long as we manage the stock well to avoid freezer burn during storage, operationally it is very good.

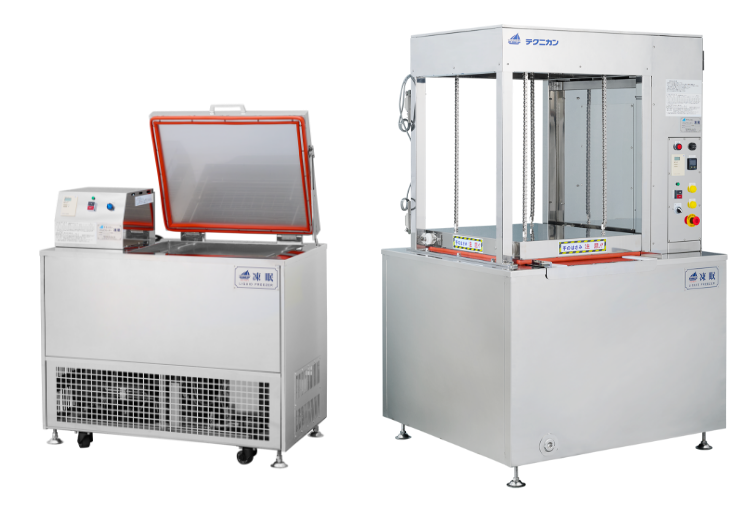

The model introduced by Seibu corporation is the S-220W, which is compact and equipped with casters, making it easy to move. The frozen items are placed in a freezing basket, which is then submerged in the TOMIN liquid tank.

Click here for information on TOMIN S-220W

Evaluation from Wholesale Customers

It seems that Seibu has received requests from clients who heard about TOMIN’s excellent reputation saying, “Please freeze with TOMIN because it’s completely different from other freezing methods.” The quality of the frozen products has also received high praise: “There’s no sense of moisture loss, and the products turn out perfectly.”

Summary

Thanks to the generosity of Seibu, we were able to compare TOMIN-frozen products with non-frozen ones. To sum up the results, none of the staff could tell the difference. When crabs are frozen, the fibers shrink, making them look thin and prone to dripping, but TOMIN -frozen products do not have such issues and are indistinguishable from non-frozen ones.

The color was also vibrant, and the texture of the crab meat was amazingly well-preserved, retaining its plumpness. The taste, only found in Hokkaido, remains intact even though Hokkaido’s eastern location means it takes time for the products to reach consumers. To-min’s ability to freeze products without losing any of their flavor is a huge benefit for doing business in such geographically challenging conditions.