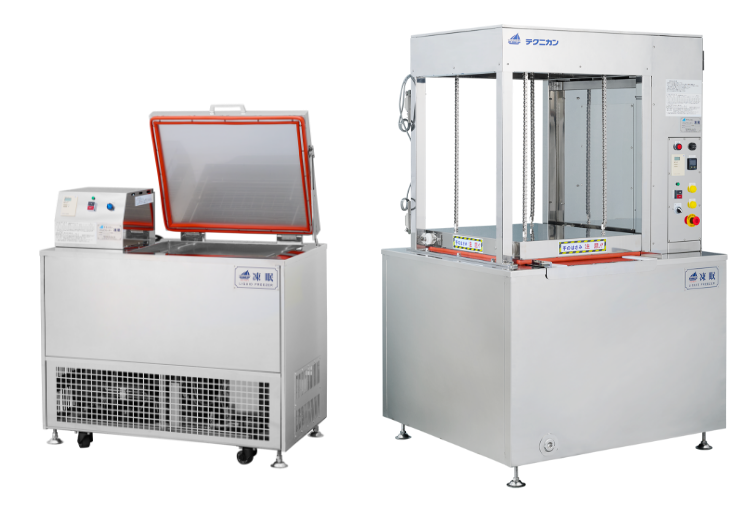

[Dried Fish x TOMIN] Advantages of switching from existing Air Blast freezing to “TOMIN” Liquid Freezing

We would introduce an example of implementation at "Akoya Hime", a Dried Sea Bream processing company in Uwajima City. In this demonstration, we observed the freezing process of Dried Sea Bream, a specialty of Uwajima.

Contents

TOMIN freezing demonstration begins

Pre-Freezing Preparation

The product being showcased today is dried Sea Bream, a famous product of Uwajima. They use Sea Bream that has been freshly harvested from the fish farm in the morning. The fish is dried for about an hour in a drying machine before being vacuum-packed.

Making Dried Sea Bream

They use extremely fresh sea bream.

Vacuum Packing the Dried Sea Bream

If the vacuum is too tight, the flesh may get crushed.

Rapid freezing with “TOMIN”

It is frozen for about 15 minutes.

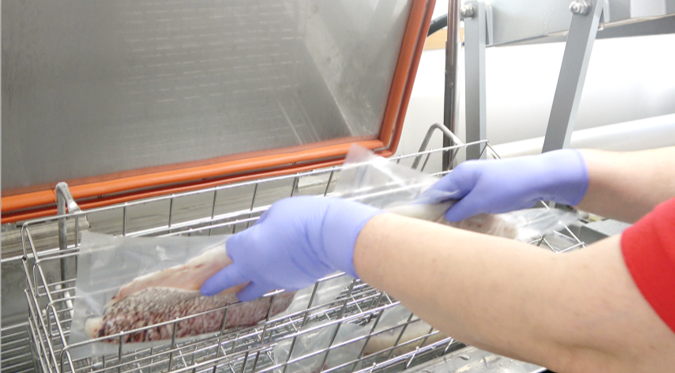

Taking out after freezing with “TOMIN”

The pack (product) is taken out from the liquid tank.

Thawing and Serving Operation

─ Fill a tray with water and thaw for about 5 minutes

─ Bake in a steam convection oven

─ Then, just plate it

Freezing comparison of TOMIN and Air Blasting

Before introducing TOMIN liquid freezer

What kind of freezing method was used before introducing TOMIN? According to Akoya Hime, they initially purchased a blast chiller (shock freezer) when they started the business. Since their roots are in pearl farming, they considered using a rapid freezer for cooking scallop adductor muscles, which are harvested only once a year. To preserve them for year-round use, they implemented air blast rapid freezing.

Much shorter freezing time improves work efficiency

At the time of implementing the air blast freezer, they thought it was the best option. However, when freezing Dried Sea Bream, the process took about 4 hours, leading to concerns about efficiency. On the other hand, with TOMIN, freezing is completed in just 15 minutes, and they’ve received high praise for the texture after thawing.

Freezing Quality of TOMIN

Akoya Hime is also very particular about the dried fish itself, using high-quality machinery. The fish comes out plump and juicy, with a crispy outer skin and tender flesh inside. Customers have expressed that the fish retains its fresh texture, and even after freezing and thawing, the crisp and fluffy qualities are not compromised. The feedback has been overwhelmingly positive, with comments like, “It doesn’t taste like it was frozen at all.” They are very satisfied with the freezing quality.

They appreciate how TOMIN allows them to deliver delicious food to their customers while keeping it in optimal condition for storage.

Summary

Our staff also had the opportunity to taste the product, and the crispness of the skin and the texture of the fish were truly impressive. The key point is the use of the steam convection oven right before serving, as the freshness of the final heating cannot be replicated. Akoya Hime has seamlessly incorporated rapid freezing into their operations, ensuring optimal storage of ingredients. Their operation is extremely efficient, thawing, heating, and serving upon order without waste.

Please contact us if you have any questions about not only the quality of our quick freezing but also our freezing operations.

Technican offers free freezing tests. We have showrooms at various locations (Hokkaido, Yokohama, Nagoya, Osaka, and Fukuoka). Please feel free to visit us.