Fresh-pressed sake frozen right in the bottle?! TOMIN makes it possible to deliver the incredible flavor of unpasteurized sake.

Izumibashi Sake Brewery was founded in 1857. The brewery is one of Japan’s rare “cultivation breweries,” which engages in all operations from farming to brewing. The brewery will be participating in the TOMIN Namazake Project created by Technican, so let’s take a closer look at this special sake brewery.

Contents

Frozen fresh-pressed sake. What is TOMIN namazake?

Namazake is sake that hasn’t been pasteurized.

Pasteurization is a typical aspect of the sake production process. Sake that has been through all other production steps is heated to sterilize it and prevent excess fermentation. Pasteurized sake is suitable for long-term storage, which is why this is the type of sake you generally find on store shelves.

As it has not been exposed to heat, namazake retains the fresh, fruity flavor of the rice. It goes down smoothly and is easy to drink, even for those who are new to it. But the most vital factor is freshness. Fermentation continues even after bottling, so the quality may change during shipping.

Mr. Kawanabe from Izumibashi Sake Brewery’s Sales Division explains, “I think it’s the case for all breweries that by the time the sake makes it to the customer, the flavor is often different from what was intended.”

TOMIN is a rapid liquid-freezing technology that makes it possible to freeze substantially faster than with air freezing. This means it is possible to literally freeze in flavor and even freeze sake in the bottle!

Before now, fresh namazake could only be enjoyed at the brewery or nearby. With TOMIN, it can be enjoyed anywhere in Japan, or even around the world! The experience of trying TOMIN namazake for the first time seems to have made an impact on Mr. Kawanabe, who has been producing sake for many years. He shares with us that the sake had a “wonderful flavor” and that “the distinctive pure taste of namazake remained intact.”

Made by hand – Izumibashi Sake Brewery’s commitment to quality

Izumibashi Sake Brewery’s motto is that “brewing sake begins with cultivating rice.” As a cultivation brewery, Izumibashi cultivates rice in-house. In order to achieve the finest quality, the brewery performs many of its sake brewing processes manually.

Mr. Tanaka, who is in charge of the koji (fermented rice), enlightens us about the process: “We light the fire under the pot of rice at 4:00 a.m. Around 6:30 a.m., the steamed rice is spread out in a thin layer to allow it to cool. The characteristics of the steamed rice differ based on the temperature and humidity reached throughout the brewing season, so we use the aroma and the feel of the rice to determine its characteristics on any given day. I use this information when instructing the team on how to wash the rice the following day and when making adjustments to the koji fermentation mold that is sprinkled on the rice. You really have to hone all your senses when brewing sake.”

Tanekiri is the name of the process of sprinkling koji mold over the rice. The steamed rice is spread out in a thin layer so the koji mold spores evenly coat every single grain. Any grains of rice that stick together won’t be completely covered by the spores, so the spores are spread by massaging the rice by hand.

The koji mold covering the rice is allowed to grow for three days inside a kojibuta(special koji box). After the rice is placed in a kojibuta, grooves are cut into the box to allow heat generated during spore reproduction to escape. The overlap and spacing between boxes is adjusted to control the temperature.

While some large breweries rely on an entirely mechanized process, Izumibashi Sake Brewery still completes certain processes by hand. The team share that they are committed to the kojibuta method, as it gives them the flexibility to adapt to the characteristics of the rice grown by the farmer and the field in which it is grown.

Intentions of the producer maintained thanks to TOMIN

The process of creating shubo (sake starter, or literally “mother of sake”) involves culturing yeast to produce alcohol by heating water in a dakidaru (traditional barrel). The temperature is manually controlled by increasing the heat or by pouring in cool water.

Mr. Inuzuka, who is in charge of the shubo, explains the process by likening it to a person’s development: “It is said that the sake grows up in the tanks of the shubo cellar until it is about 20 years old, this entire period being one that will determine its personality. Here it will encounter a number of microorganisms, meet with stress, and receive nutrients, all while building its character.”

As the word “mother of sake” implies, sake breweries produce sake with love, just like a mother raising her child.

Another manual process undertaken at Izumibashi Sake Brewery is the making of moromi, which is created by mixing rice, water, koji, and yeast together and then allowing the mixture to ferment. In a large facility, this process has to be automated. However, to prevent the steamed rice from being crushed, it is stirred manually, and exceptional care is taken during the process by the stirrers to evenly mix the ingredients. They rely on how the mixture feels in their hands when assessing how to proceed.

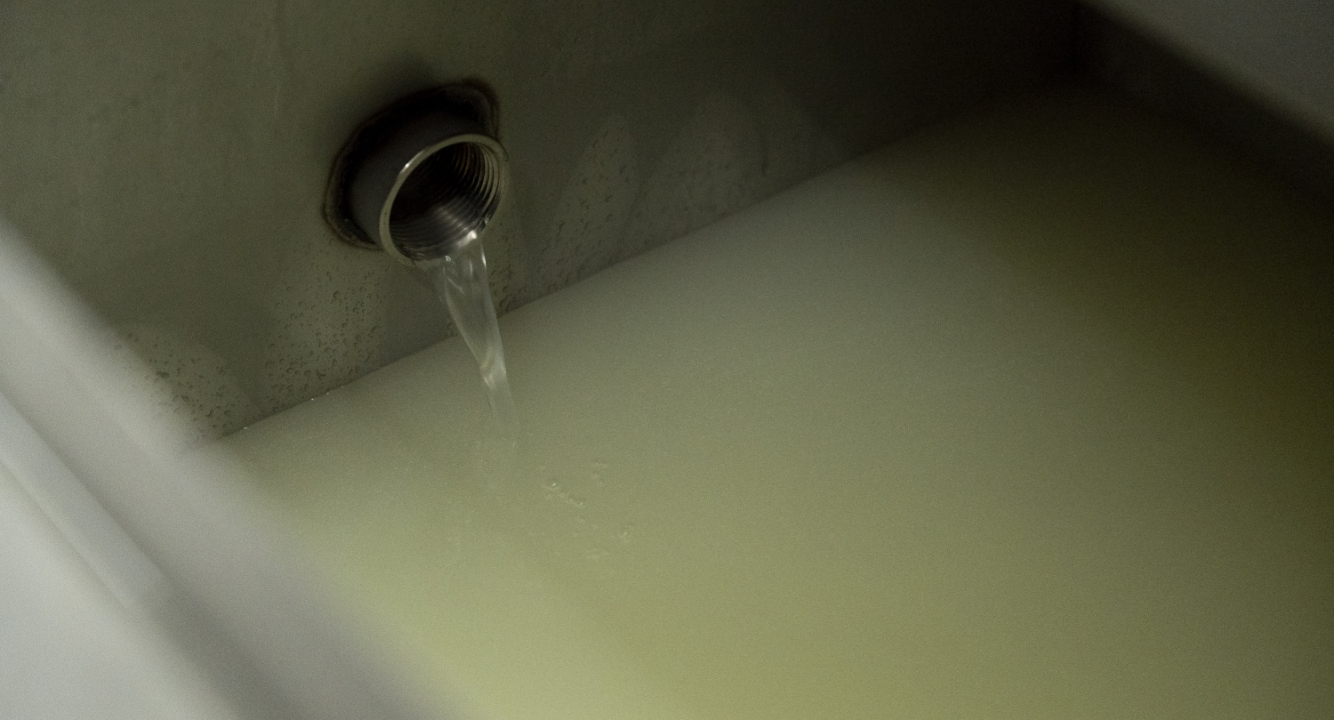

Joso is the process of pressing the moromi, which separates it into genshu (undiluted sake) and sake lees. The transparent liquid that is squeezed out becomes sake and is bottled.

It takes many closely managed manufacturing processes to produce sake with an exceptional taste, and brewers take every single one of those processes very seriously. With the TOMIN Namazake Project, we will offer frozen sake that boasts the taste of recently produced, unpasteurized sake intended by the brewer.

Enjoy fresh unpasteurized sake throughout Japan! The TOMIN Nama Sake Project.

Technican will be partnering with around 25 sake breweries, including Izumibashi Sake Brewery, for the TOMIN Namazake Project. The project involves working with sake breweries throughout Japan to sell each brewery’s fresh-pressed namazake following TOMIN Liquid Cryo-Freezing.

Namazake has a clean, refreshing, fruity flavor. It goes down well, even for those who usually drink liqueurs or who aren’t fond of sake, so why not take this opportunity to try it?

We’ll be expecting you!

Izumibashi Sake Brewery

Based on the belief that "sake brewing starts with rice cultivation," we are one of the few breweries in Japan that cultivates and brews sake rice in Ebina City and neighboring areas, from cultivation to milling and brewing.

We carefully brew sake from reliable rice grown with the blessings of the sun and the earth, and all of our sake is junmai sake. And all of our sake is junmai sake. We aim to make sake that can be drunk in such a comfortable manner.