What is quick freezing? Important factors, benefits and types of quality preservation

This article provides a definition of quick freezing, its benefits, and important factors to preserve quality. The types of quick freezing will also be explained.

Contents

What is quick freezing?

Definition and difference from slow freezing

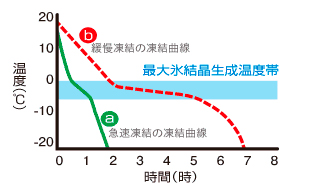

The moisture in food generally changes from water to ice between -1°C and -5°C. This interval is called the maximum ice crystal formation zone. The term “quick freezing” refers to passing through this temperature zone in a short time.

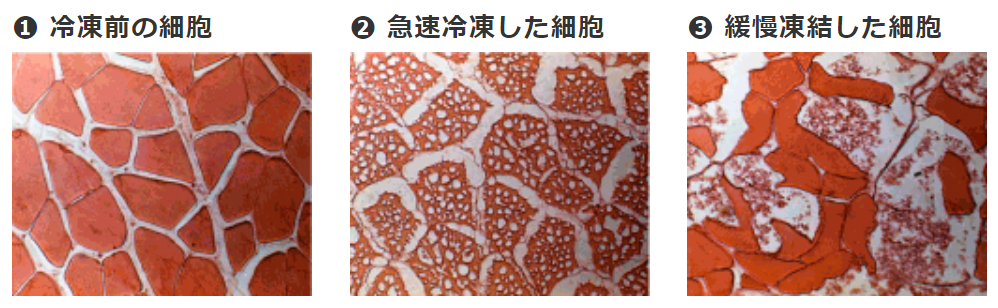

Quick freezing has the advantage that the ice crystals formed in the food become finer and cause less damage to the food.

On the other hand, freezing in an ordinary freezer is called “slow freezing.” If the freezing process takes a long time, the ice crystals become enlarged, the texture of the food deteriorates, dripping occurs due to the damage to the cell membranes, and food components are separated due to differences in melting points, resulting in a deterioration of food quality.

Quick freezing is a technology that restores the food to its pre-freezing state as much as possible.

Photo source: Japan Frozen Foods Association

Advantages of Quick Freezing

Can be kept fresh

Since ice crystals are formed finely, we can freeze foods without destroying cells or significantly reducing damage to them. This minimizes drips during thawing, allowing meat and fish to maintain a high level of freshness after thawing.

Loss Reduction

If high freshness storage becomes possible for a long period of time by freezing, even raw foodstuffs can be planned throughout the year. Food loss can be reduced at various sites because the food can be thawed and used when and as much as desired.

Reduction in unit purchase cost

It is possible to purchase and store seasonal ingredients in bulk at inexpensive times. Therefore, you can reduce the unit price.

By controlling the timing of shipments, gross profit margins will change for the same product if it can be produced and sold at the timing that maximizes its value.

Operational Efficiency

“A central kitchen or processing plant can prepare and quickly freeze products in batches. By doing so, work can be reduced or even eliminated during peak periods such as year-end.

Expansion of sales channels

“Products that were once thought impossible to freeze because of quality loss can now be quickly frozen. This greatly expands the trade area. Now, it is possible to sell these products far away, overcoming both time and distance.

Elements of quick freezing important for quality preservation

Takes the heat off fast.

Please note that quick freezing does not necessarily mean lower temperatures require shorter time.

Equipment designed for quick freezing at -30°C will freeze faster than a -60°C freezer stocker. The thickness of the product is also an important factor. Thinner products are easier to freeze quickly, but the thicker they are, the more time it takes for ice crystals to form in the center at once.

Preventing Product Drying

As air temperature decreases, the amount of moisture the air can hold also decreases. Therefore, the inside of a freezer is extremely dry. To achieve quick freezing, this dry air is blown strongly onto the product, which can lead to the removal of moisture from the surface of the product. For products that are consumed raw, it is especially important to prevent drying. The best conditions for quick freezing involve minimizing the drying of the product.

Preventing Uneven Freezing

Inside a freezer, it is difficult for all areas to have the same conditions. There will always be spots that are more exposed to cold air and others that are less exposed. Ensuring consistent product quality is crucial, and for this reason, it is important to freeze items that are as thin and uniform in thickness as possible. This makes rapid freezing easier.

Types of Quick Chillers

Blast chillers, shock freezers

Airblast quick chillers are the most common choice when you want to “quick freeze” or “quick cool.”

This product is designed to cool products in a hotel pan attached to the side by a large fan in one go. This product is often used in high-volume cooking situations where freezing and cooling can be performed in a single unit.

Liquid Freezing Machine

Liquid Freezers have an overwhelming advantage in terms of heat exchange speed. The freezer is used to immerse packed products in a chilled alcohol solution and freeze them. This freezing method is so fast that thin foods, such as meat steak can be completely frozen in a few minutes, and the quality of the meat is excellent.

We are confident in recommending the “Liquid Freezer TOMIN” produced by Technican, a pioneer company in liquid freezing.

Special Air Blast Rapid Chiller

There are various types of freezing systems, such as those that create a special air current to prevent drying, and those that use electricity to regulate water molecules while freezing. There are various merits and demerits, and the best way to find out is to actually try them out to see if they are suitable for your food products, and to listen to what the manufacturers and people who have introduced them have to say about them. However, what they all have in common is that they are designed for “quick freezing. No matter what technology is used, “quick freezing” is the most important factor in assuring quality.

Conclusion

Quick freezing is now a key technology in the food industry. Thanks to the creativity of manufacturers and advancements in freezing machines, frozen products are as good as fresh and chilled ones. More stores specializing in frozen foods are opening, and supermarkets and convenience stores are expanding their frozen food sections to compete. Although fresh food tastes best, the benefits of quick freezing are becoming more appreciated. Frozen food offers many efficiencies in production and meets the needs of consumers better than fresh food in many ways.